1-877-795-2278 | info@aircraftspruce.ca

Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

SAME DAY SHIPPING ON ORDERS PLACED BY 2 PM | 877-795-2278

Tekton 3/8 Inch Drive 6-Point Flare Nut Crowfoot Wrench Set With Rack

Select Set:

14-Piece (5/16 - 1-1/16 In.)

14-Piece (5/16 - 1-1/16 In.) 18-Piece (8-27 Mm)

18-Piece (8-27 Mm) - JUMP TO

- Overview

- Storage Features

- Reviews

- Q&A

Overview

|

Tekton 3/8 Inch Drive 6-Point Flare Nut Crowfoot Wrench Set With Rack

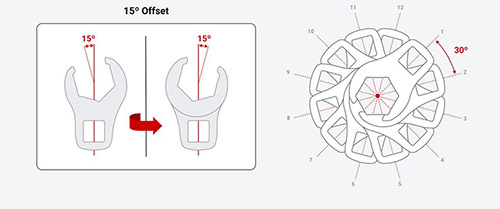

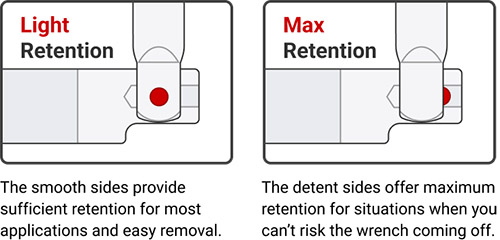

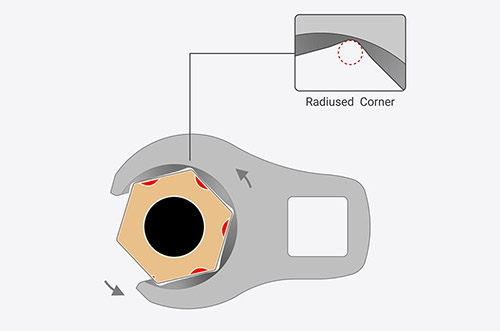

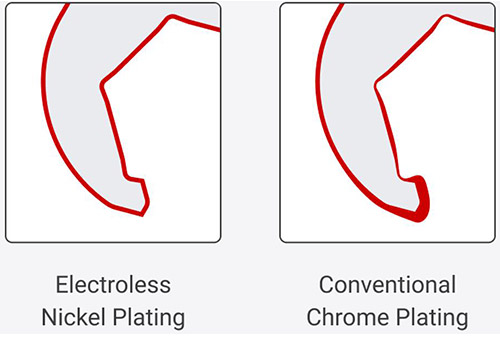

Optimized for Engagement Our deep, 6-point design maximizes your contact with fittings and prevents slipping. The sizes of our flare nut crowfoot wrenches scale optimally with fitting depths to achieve the best possible combination of engagement, access, and strength. Lean Design Our design is leaner than conventional 6-point crowfoot wrenches, giving you more room to work in tight spaces. Reinforced Jaw Strength We reinforced our wrenches with material where it matters most to avoid high stress concentrations and prevent the jaws from spreading. Part of a System of Access Wrenches Tekton flare nut crowfoot wrenches have a 6-point opening and deep walls to maximize contact with fittings. They complement our other access wrenches, including crowfoot, service, and angle head wrenches. 15° Offset Increases Access Angles The jaw opening is offset 15 degrees from the center of the wrench so that it can be flipped over to gain additional access angles.  Two Levels of Retention  Prevents Fastener Round-Off Radiused corners help avoid fitting round-off by applying force to the fitting’s flat sides, rather than its corners.  Smooth, Satin Nickel Finish The flare nut crowfoot wrenches are abrasive blasted to create a smooth, satin nickel finish. Electroless Nickel Plating for Corrosion Resistance The electroless nickel plating finish is easy to wipe clean and highly resistant to corrosion. Uniform Coverage and Better Fit The electroless process applies a uniform coating to the entire tool surface. By comparison, electroplating, including conventional chrome plating, has varying thickness across the tool because the plating thickness depends on the electric current density at each point on the tool. The uniformity of an electroless coating has two major advantages: Complete corrosion protection on interior surfaces. Better fit in the wrench jaws because plating material does not accumulate at the jaw tips.  Clear Size Markings The wrench sizes are laser engraved on the side of each wrench with a large, permanent marking that’s easy to read.   Manufactured in Michigan The flare nut crowfoot wrenches are made entirely in the USA with USA-sourced materials. Machining, broaching, blasting, plating, and engraving take place at our Grand Rapids, Michigan, manufacturing facility. |

Storage Features

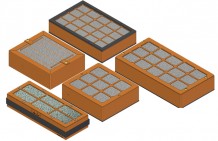

- Custom-Fit for Tekton Flare Nut Crowfoot Wrenches

- Easy One-Handed Wrench Removal - The wrenches rest in size-marked slots, making it easy to take the tools in and out without resistance.

- Portable Rack - A narrow lip along the edge of the rack makes it easy to pick up and carry the wrenches to your workpiece.

- Compact Footprint Saves Drawer Space

- Durable Single-Piece Polypropylene Construction

Aircraft Spruce Canada

Aircraft Spruce Canada