|

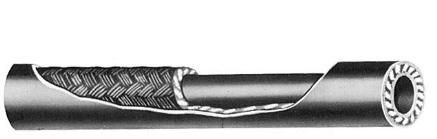

This popular style hose is used in medium pressure aircraft hydraulic, fuel, oil and coolant systems. An inner tube of seamless synthetic rubber is reinforced with a synthetic-impregnated single-wire braid over a single cotton braid and an outer cover of synthetic-impregnated oil-resistant cotton braid. Operating temperature -65F to +250F. Conforms to MIL-H-8794 (supersedes MIL-H-5511A). Used with Aeroquip 491 hose fittings. View 303 Data Sheet |

Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

Custom FAA Approved Hose Assembly Order Form

HOSE DUPLICATION

If you have the Eaton part number off your current hose, you can enter it here and add the item directly to your cart. If you don't have the Eaton number, you can use the selector above to build a hose to your specifications. All hoses are FAA Approved and use only Eaton components.

CUSTOM QUOTES | BULK ORDERS

For custom quotes, bulk orders and special requests, please email hoseshop@aircraftspruce.com or call our sales desk at 877-593-9848.

CUSTOM QUOTES | BULK ORDERS

For custom quotes, bulk orders and special requests, please email hoseshop@aeroperformance.com or call our sales desk at 877-593-9848.

Eaton Part Number: |

|

| Price: |

Hose Information

-

Eaton Aeroquip 303

-

Eaton Aeroquip 306

306 hose is commonly used with low pressure air or vacuum instrument systems, automatic pilots and lines to pressure gauges. The Inner Tube is a seamless synthetic rubber compound with a single cotton braid reinforcement and a synthetic rubber cove outer cover. Temperature range -65F to +160F

View 306 Data Sheet -

Eaton Aeroquip 666

Eaton/Aeroquips 666 medium pressure PTFE hose is used in hydraulic and pneumatic applications at pressures up to 1500 psi. The hose is unaffected by all fuels, oils, alcohols, coolants, or solvents commonly used in aircraft. Construction of Aeroquip 666 hose is of spiral extruded Teflon resin for the inner tube with a reinforcement and outer cover of Type 300 Series stainless steel wire braid. Operating temperature is -65F to +450F.

View 666 Data Sheet -

Eaton Aeroquip AE466

Eaton/Aeroquips integral silicone firesleeve on PTFE hose assemblies is a combination that meets the fire test requirements of TSO-C53A Type D and TSO-C75 Type III A and III B.

The Silicone sleeve is applied directly onto the metal braid to form a smooth, tight bond. This Hose eliminates the need for band clamps while providing better flexibility to the standard orange fire sleeve. Temperature range of -65F to +450F. Only available in brown.

View AE466 Data Sheet -

Eaton Aeroquip AE701

Eaton/Aeroquips 701 hose is widely used for aircraft fuel and oil lines where flexibility and light weight are prime considerations. The hose is made with a synthetic rubber inner tube with two layers of stainless steel wire braid reinforcement. Because of its lighter weight and lower operating pressure than type 303 hose, it is not recommended for hydraulic lines. AE701 hose has no shelf life and is the upgraded version of 601 hose. Operating temperature range of -65F to +300F. Used with Aeroquip 816 hose fittings.

View AE701 Data Sheet -

AE102 Firesleeve

Sleeving used to meet the fire resistance requirements of FAA TSO-C53a or TSO-C75. AE102 firesleeve, identified by its orange colored outer surface, has a continuous operating temperature range of -65F to +450F. This fire sleeve can be used for all fuel, oil and hydraulic lines. 900591B Clamps are used to secure the firesleeve material on each end over the hose assembly.

Other styles of protective sleeve/chafe guard are also available. Please contact the hose shop directly.

View AE102 Data Sheet

Frequently Asked Questions

-

Frequently Asked Questions

SearchQuestions Answers My hose has orange firesleeve, can I replace it with the brown silicone integral firesleeve? Yes, select AE466 for the hose type and proceed with other specifications from the dropdowns. My hose is 10 years old, do I really need to replace it? Though your hose may continue to be serviceable at the moment, it is recommended to replace hoses after 8 years or at overhaul of the engine. My mechanic told me that Teflon hoses are lifetime, is that true? No, regardless of hose type, it is recommended to replace the hose after 8 years or at overhaul of the engine. My aircraft's engine is being overhauled and hoses were replaced 5 years ago, do I need to replace them? We recommend sending your hoses to our hose shop for inspection, pressure testing and possible recertification. If the hoses pass, a second tag will be added to the hoses with the date of recertification and the hoses should be serviceable until they are 8 years old or next engine overhaul. This can be done at a fraction of the cost of new hoses. Any hoses that fail will be quoted and offered to be built new. Do you offer hose kits for specific airframe or engine models? Though there is certainly some convenience in this, we have found the majority of engines are modified in ways that change the lengths and angles on hoses. Due to this, we do not offer hose kits. Please contact the hose shop to help identify your necessary hoses or send them in for duplication. Are there minimum lengths for hose types? Yes, AE466 has a 6" minimum length. Rubber hoses tend to have a 4" minimum length. My hose goes between the engine baffling and the firewall, does it need firesleeve? All hoses within the engine compartment are recommended to have firesleeve. How can my hose be identified for replacement? The surest way is to send your hose to our hose shop for duplication. If this is not an option, we recommend looking up the part number in your engine / airframe illustrated parts catalog. Providing our hose shop with the P/N on id band is an option however it is only successful if the proper P/N was put on the ID band. The original hose P/N may not be applicable if any modifications have been done to the engine. Lastly, hoses can be broken down by hose type, size, firesleeve or no firesleeve, length and angle of fittings. I want to install a transducer for fuel flow metering, what hoses will I need to install with it? The length of the currently installed hose will need to be provided to our hose shop. Generally, it is recommended to install the transducer in the middle of the length of hose. The transducer length would need to be provided as that length will be deducted from the two hoses that will be installed to the transducer. If you want the transducer in a specific position within the engine compartment, the lengths of the two replacement hoses will be determined. Why do I need an angled fitting, can't the hose bend however I want it to? Each hose type has its own maximum bend radius. If bent beyond that, the hose would be expected to crack rendering it no longer serviceable. Due to this, hoses use either a straight, 45 degree or 90 degree fitting. I have a drain / vent line that only has a fitting on one end. Do all hoses have to have a fitting on both ends? We can build a hose with a fitting on only one end if that meets your application. Please contact the hose shop. Can you recertify my hose that isn't Eaton / Aeroquip brand? No, the hose shop is certified by Eaton to only work with Eaton hoses. We would be happy to build you an Eaton equivalent of your hose. I selected the wrong hose on my order, what should I do? Contact our hose shop immediately. If your hose hasn't been cut, we can try and accommodate the change. Otherwise, hose orders are non-cancellable and non-returnable as each one is custom made. I received my hose and my mechanic said I should have had firesleeve on it, do I need to order another hose? Not necessarily. The orange firesleeve can be added over a straight fitting after a hose has been built. The firesleeve can be added and the proper P/N for the firesleeved hose will be on the hose tag. Please contact our hose shop and send us the hose. If I send you my hoses for duplication can I have them back? Yes, we would be happy to send back your old hoses along with your new hoses. Many customers add tape to their old hoses identifying where they go on the aircraft. It makes sense for you to match that old hose with the new to know exactly where it goes.

Aircraft Spruce Canada

Aircraft Spruce Canada