1-877-795-2278 | info@aircraftspruce.ca

Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

SAME DAY SHIPPING ON ORDERS PLACED BY 2 PM | 877-795-2278

Alternator Drive Coupling Tool Kit ADCKIT2

$438.00/Each

Part# 08-17440

MFR Model# ADCKIT2

MFR Model# ADCKIT2

Overview

|

Alternator Drive Coupling Tool Kit: Designed for proper installation, removal and testing of alternator drive couplings found on many Continental Aerospace Technologies piston engines.

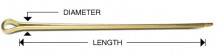

Includes adapter to support Alternator Drive Coupling Inspection and Installation on Continental C-75/85/90/115/125/145,E-165/185/225,O-200/300,IO-240/360 series engines, in addition to Continental O-520/550 series engines. Alternator Coupling Tools are purpose-built to make it easy for mechanics to inspect this critical component and simplify coupling installation and removal. The tool kit consists of a zinc-coated coupling spanner wrench and unique coupling gear socket with steel housing and aluminum gear engagement, designed to protect the steel coupling gear from damage during maintenance. Together, these tools allow the coupling to be held in place (mounted on the alternator or free-standing) while the coupling gear slippage is checked with a calibrated 3/8” torque wrench (as specified in the engine maintenance manual). The alternator drive coupling plays an important role in engines with direct-drive, gear-driven alternators. The coupling provides a shear point, protecting the engine from damage should the alternator fail. However, it is imperative that the coupling be installed properly and inspected every 500 hours or any time that the alternator is removed from the aircraft. This critical component has been the subject of several Service Bulletins (SBs) and Special Airworthiness Information Bulletins (SAIBs) because an out-of-tolerance or improperly installed coupling can lead to catastrophic engine failure. The lack of specialized tools to perform these tasks has made compliance difficult for many shops, increasing the risk that these critical inspections are not being performed in the field. In addition, alternator coupling slippage is a frequent cause of low alternator output. Without the tools to properly inspect the coupling, these failures are often mis-diagnosed as a failure of the alternator, resulting in wasted time and money for both shops and owners. |

Eligibility

- Includes adapter to support Alternator Drive Coupling Inspection and Installation on Continental C-75/85/90/115/125/145,E-165/185/225,O-200/300,IO-240/360 series engines, in addition to Continental O-520/550 series engines.

In The Box

- Steel Spanner- Designed for Elastomeric Couplings Only

- Steel/Aluminum Drive Gear Socket

- Small bore engine adapter

Q&A

Please note, Aircraft Spruce Canada's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Canada assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Aircraft Spruce Canada

Aircraft Spruce Canada