1-877-795-2278 | info@aircraftspruce.ca

Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

THE AVIATION SUPERSTORE FOR ALL YOUR AIRCRAFT & PILOT NEEDS | 877-795-2278

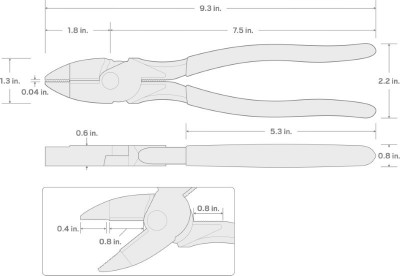

Tekton 9-1/2 Inch Lineman's Pliers

$43.50/Each

Part# 12-06697

MFR Model# PGF30009

MFR Model# PGF30009

Overview

Generously sized with a strong, heavy build, these pliers have flat, squared off jaws and large side cutters for wiring electrical circuits, installing distribution panels, and maintenance and repair of utilities and appliances.

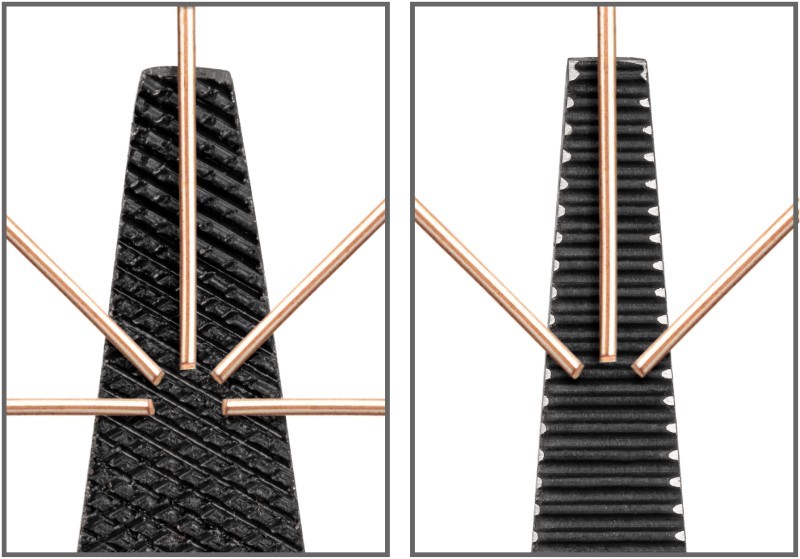

Broad, Flat Jaws Nearly square, with a straight, flat nose, these jaws can bend thin, flat pieces like metal tabs, mounting brackets, and cable clamps to a crisp right angle.  Gap Spacing Holds Wire Ends A small gap (1 mm ±0.5 mm) allows the jaw faces to remain nearly parallel while holding the ends of multiple wires, keeping each wire flat and in position while twisting them together.

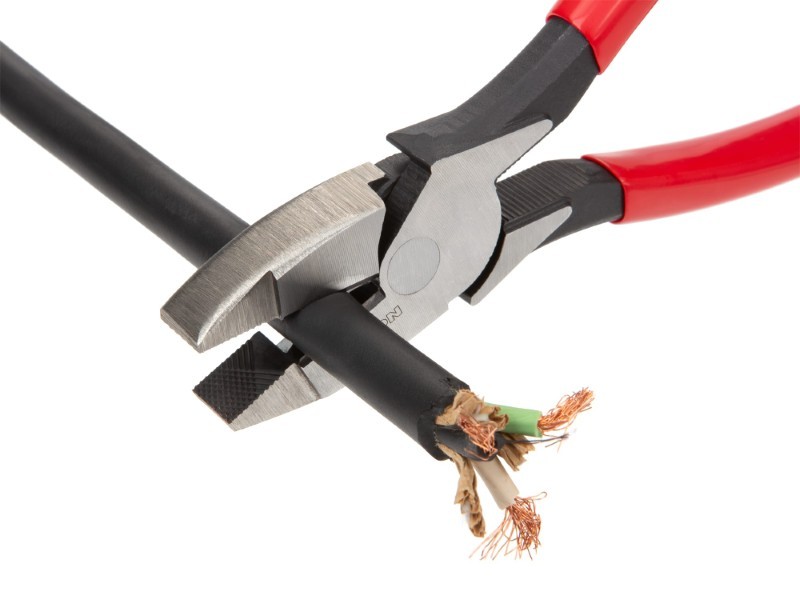

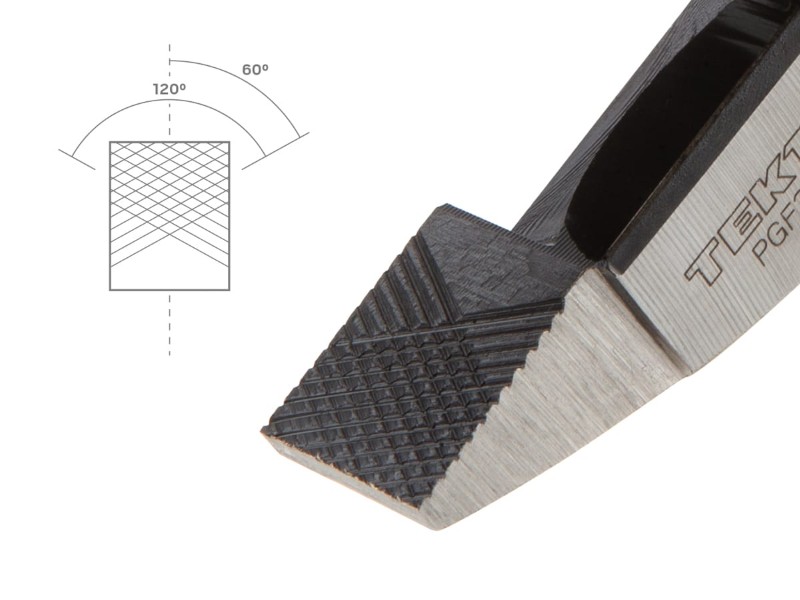

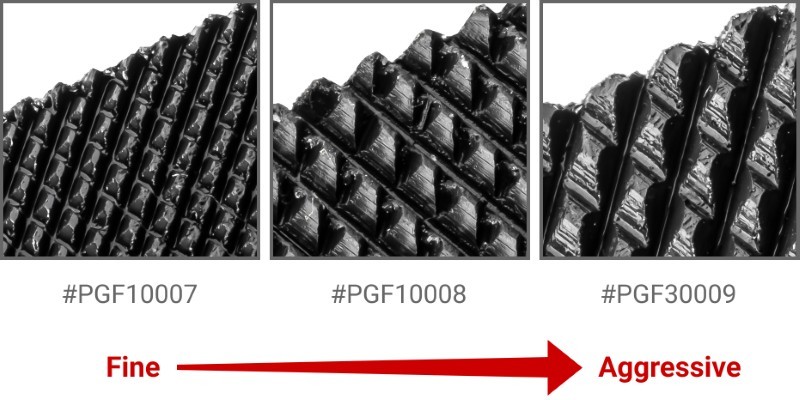

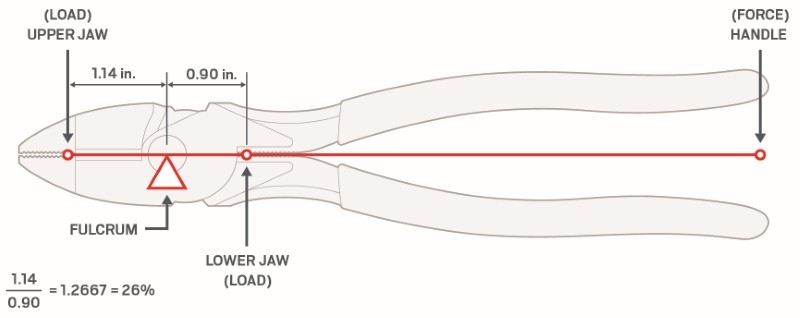

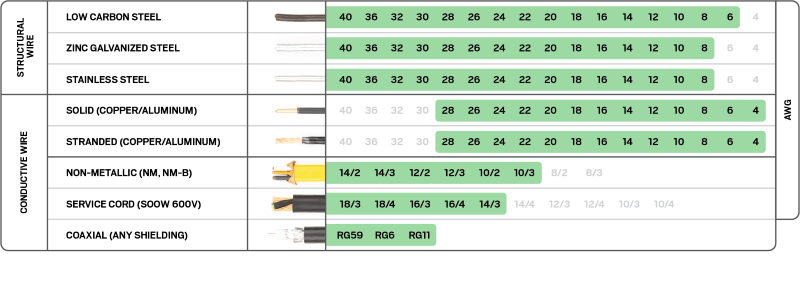

Crosscut Teeth Oriented at 120 degrees to each other, the serrations are cut in two passes to form regularly-spaced, diamond-shaped teeth.  Grip in All Directions Unlike straight serrations where the grip strength varies relative to tooth direction, a crosscut pattern grips evenly in any direction.  Range of Tooth Types Smaller pliers with fine teeth are best for smaller precision applications and result in less marring of the work piece. Larger pliers with more aggressive teeth provide a stronger grip on less delicate parts.  High-Leverage Lower Jaws Because they are located below the pivot and a little closer to the fulcrum, the lower jaws can exert about 30% more force than the main jaws, useful for crushing functions like closing wire clamps and crimping connectors.   Clean Cut with Minimal Effort Machining the blades to an optimized 65-degree angle allows them to be strong yet sharp, producing a satisfyingly smooth, clean cut that requires minimal effort.  INDUCTION HARDENED: After the full pliers have been heat treated, a secondary induction-heating process hardens just the blades to 58-64 HRC, making them extremely durable and able to cut tougher materials. KNIFE-TO-KNIFE: Comprised of two opposing blades that meet in the center, it is an extremely reliable cutting method, especially for harder wires. For a clean, low-effort cut, it requires a high level of manufacturing expertise to produce the near perfect alignment of the blades. When this cannot be consistently achieved, some manufacturers may turn to a less effective knife-and-anvil design (one knife blade, one blunted blade) that doesn't require such precise alignment. Cutting Capacities  Wide Profile Handles Generous in overall size, the handles have an extra wide, gently rounded profile that creates a large, smooth contact surface. This spreads out the pressure against your hand so you can comfortably squeeze as hard as needed.  Lean and Practical Grips Single-layer vinyl grips offer a bit of comfortable cushion and provide a smooth, yet nonslip surface. They're slim, not thick and bulky, so they stay out of the way when space is tight and are always easy to handle, even with gloves on.  Non-absorbing and resistant to most common fuels, lubricants, and cleaners. Won't get soft or sticky over time. Easy to wipe clean. |

Features

- Jaws can bend thin, flat pieces like metal tabs, mounting brackets, and cable clamps to a crisp right angle

- Gap spacing holds wire ends keeping each wire flat and in position while twisting them together

- Crosscut teeth distribute force evenly for sure grip in any direction

Q&A

Please note, Aircraft Spruce Canada's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Canada assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Aircraft Spruce Canada

Aircraft Spruce Canada