1-877-795-2278 | info@aircraftspruce.ca

Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

SAME DAY SHIPPING ON ORDERS PLACED BY 2 PM | 877-795-2278

Tekton 1/4 Inch Drive 90-Tooth Dual-Direction Micrometer Torque Wrench (20-200 in-lb)

$130.90/Each

Part# 12-06872

MFR Model# TRQ50402

MFR Model# TRQ50402

Overview

|

1/4 Inch Drive 90-Tooth Dual-Direction Micrometer Torque Wrench

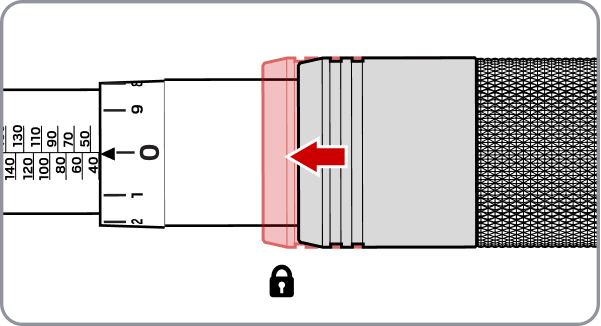

Apply Torque with Confidence Every feature was designed to instill confidence in the wrench's accuracy and control during operation.

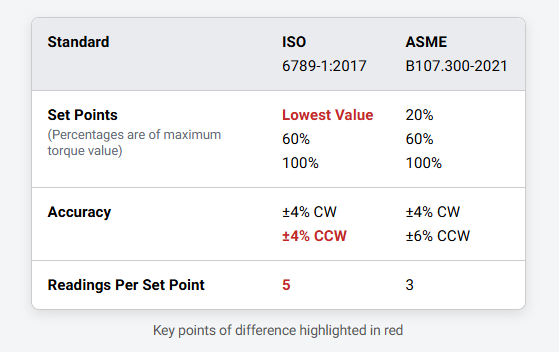

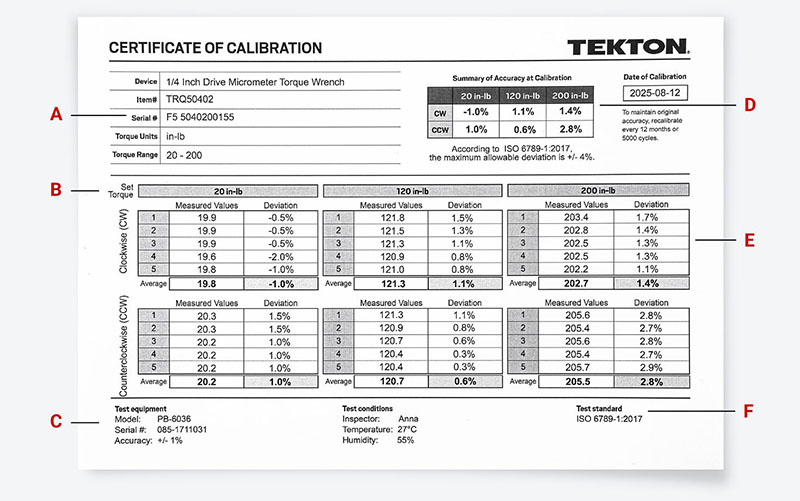

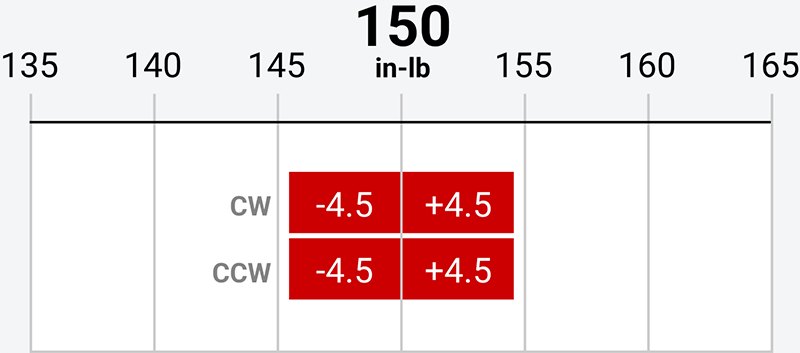

Accurate Within ±3% for Both Directions The actual calibration accuracy will be stated on the certificate for your wrench, and will be within ±3%. Example of maximum expected error:   Full-Range Calibration Using the ISO Standard This torque wrench is calibrated to the ISO standard. The ASME standard is more commonly used, but the ISO requirements are stricter in a few key ways:

|

Specifications

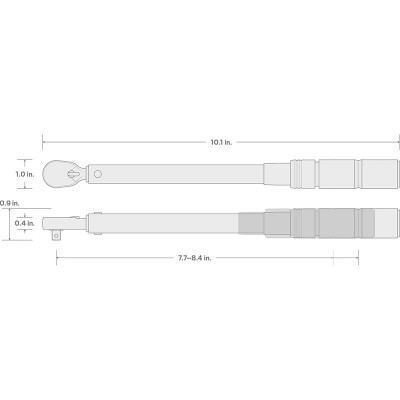

- Drive Size: 1/4 in.

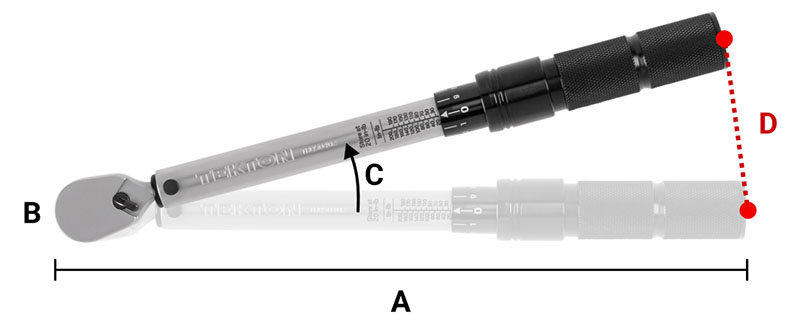

- Tooth Count / Swing Arc: 90-Tooth / 4º

- Head Style: Fixed

- Torque Range: 20 - 200 in-lb

- Torque Calibration Test Points: 20, 120, 200 in-lb

- Unit Scale: in-lb

- Minimum Increment: 1 in-lb

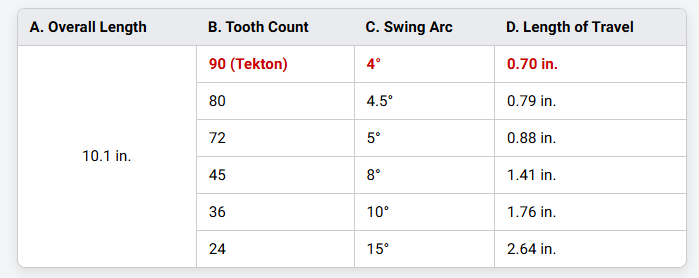

- Measuring Direction: Clockwise, Counterclockwise

- Torque Accuracy: Within ±3% CW/CCW

- Feedback: Mechanical Click

- Standards: (meets or exceeds): ISO 6789-1:2017

- ASME B107.300-2021

- Working Length: 7.7 - 8.4 in.

- Overall Length: 10.1 in.

- Item Weight: 0.73 lb.

- Country of Origin: Taiwan

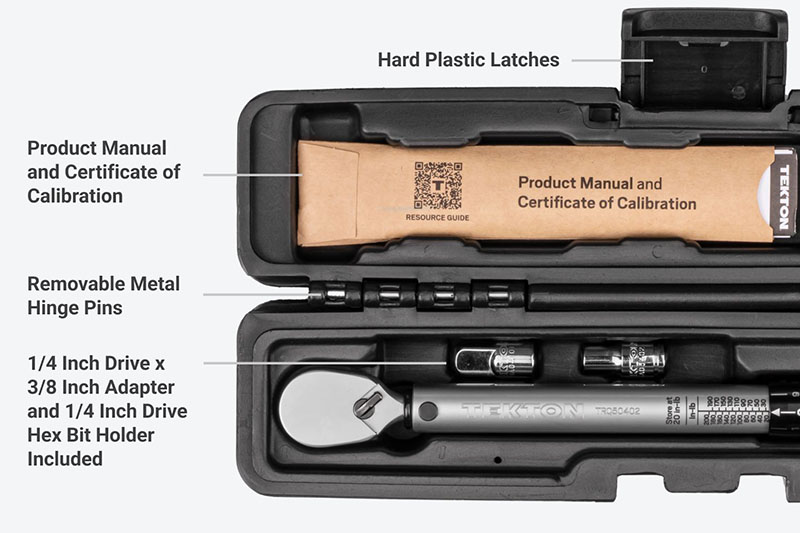

- Other Included Items:

- Case

- Product Manual

- Certificate of Calibration

- 1/4 Inch Drive Hex Bit Holder

- 1/4 to 3/8 Inch Drive Adapter

Documents

Q&A

Please note, Aircraft Spruce Canada's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Canada assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Aircraft Spruce Canada

Aircraft Spruce Canada