Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

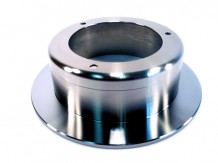

215CC Tempest Overhauled Vacuum Pump

MFR Model# 215CC-OH

- JUMP TO

- Overview

- Documents

- Reviews

- Q&A

- View in Catalog

Overview

|

When Tempest receives a core, it is disassembled and all carbon is discarded. They never re-use carbon or the center stator. All parts are replaced with the possible exception of the end plates. The hard anodize is stripped from the center stator and the stator is inspected for cracks. They then perform a reconditioning of the I.D. After the reconditioning process, each stator is meticulously inspected for proper dimensions. The stator then receives a new hard anodize coating. They inspect 100% of the parts that we re-use in the overhaul process to make sure that each part meets the requirements for our FAA-Approved process specification 203-6-1009. Additional core charge added to purchase at time of checkout |

Documents

Reviews

Easy install and it really sucks

Tempest Vacuum Pump Dry Air Counter-Clockwise - Overhauled - 215CC

Works as designed.

Tempest Vacuum Pump Dry Air Counter-Clockwise - Overhauled - 215CC

Recently purchased a new airplane and discovered during inspection the vacuum pump was faulty. With a quick search on Aircraft Spruce, we located a replacement and within days it was installed and working. Tempest pump fit perfectly and the price was competitive.

Tempest Vacuum Pump Dry Air Counter-Clockwise - Overhauled - 215CC

Tempest Vacuum Pump Dry Air Counter-Clockwise - Overhauled - 215CC

Good

Tempest Vacuum Pump Dry Air Counter-Clockwise - Overhauled - 215CC

Pump definitely sucks!! 5 stars

Tempest Vacuum Pump Dry Air Counter-Clockwise - Overhauled - 215CC

above average longevity, comes with gasket

Tempest Vacuum Pump Dry Air Counter-Clockwise - Overhauled - 215CC

Working

Tempest Vacuum Pump Dry Air Counter-Clockwise - Overhauled - 215CC

Fast delivery well packaged

Tempest Vacuum Pump Dry Air Counter-Clockwise - Overhauled - 215CC

Fills the need

Tempest Vacuum Pump Dry Air Counter-Clockwise - Overhauled - 215CC

Q&A

Please note, Aircraft Spruce Canada's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Canada assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Yes that would be an acceptable core.

Yes they will accept that core.

The warranty is 2 years or 1000 hours from time of install.

No, it does not.

The -9 has a drain port machined in drive end to help get rid of moisture such as engine oil. Usually used on Cessna 150, O200 engine where air pump is mounted upside down on front bottom of engine. Internal workings, pressures and flows are the same as the 3215CC, 215CC....etc

No, the overhauled units do not.

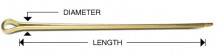

CC: Stands for Counter-Clockwise. (A model ending in "CW" would turn Clockwise). In aviation, rotation direction is determined as viewed from the rear of the engine (accessory case) looking forward. From the Pilot's Seat: If you are sitting in the cockpit, the pump rotates Counter-Clockwise. Looking at the Mounting Pad: If you are standing at the back of the engine looking at the pump installed on the accessory pad, it rotates Counter-Clockwise. Do not install a "CC" pump on an engine drive pad that spins Clockwise. Doing so will immediately destroy the pump's internal carbon vanes and rotor upon startup. If you are unsure which way your engine's accessory drive pad turns, you can briefly crank the engine (with the magneto switch OFF) while observing the drive pad to visually verify the rotation before installation.

Aircraft Spruce Canada

Aircraft Spruce Canada