Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

Electronics International Fuel Flow Transducer FT60

MFR Model# FT-60

Overview

|

Flow Transducer. For use in Aircraft with engine-driven fuel pumps & Horsepower up to 350 HP. E.I. products include all documentation and certifications |

Specifications

- Fitting: 1/4" female NPT

- Flow Rate: .6 to 70+ GPH

- Pressure Drop: .6 psi at 30 GPH / 2.3 psi at 60 GPH

Documents

Reviews

Fairly quick on delivery (in stock) at relatively good price. Easy install and fixed the issue with my fuel flow indication on the G3X.

Electronics International FT60 Fuel Flow Transducer For < 350HP / Fuel Pump

Installation was quick and easy. Close to accurate AFAIK, but will track FF. Darn thirsty engine!!!

Electronics International FT60 Fuel Flow Transducer For < 350HP / Fuel Pump

Used this product before. Works great. Was able to calibrate it with my Dynon Skyview.

Electronics International FT60 Fuel Flow Transducer For < 350HP / Fuel Pump

Electronics International FT60 Fuel Flow Transducer For < 350HP / Fuel Pump

Nice size, well made, just right for experimentals.

Electronics International FT60 Fuel Flow Transducer For < 350HP / Fuel Pump

Previous one lasted 1000 hours then failed. This is direct replacement, hope it does better.

Electronics International FT60 Fuel Flow Transducer For < 350HP / Fuel Pump

Great product, fast shipping and good value

Electronics International FT60 Fuel Flow Transducer For < 350HP / Fuel Pump

Electronics International FT60 Fuel Flow Transducer For < 350HP / Fuel Pump

They arrived in Australia in 4 days and not damaged

Electronics International FT60 Fuel Flow Transducer For < 350HP / Fuel Pump

Overall satisfied with the CGR30-P engine analyzer, however the fuel flow transducer failed after approx 300 hrs. Replacement works great.

Electronics International FT60 Fuel Flow Transducer For < 350HP / Fuel Pump

Q&A

Please note, Aircraft Spruce Canada's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Canada assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

The warranty is 1 year and can only be returned to us with in 30 days not installed (new condition). If you need to confirm the FT 60 will work please let us know your engine make or model or contact EI.

The FT60 is to be used in an aircraft with engine-driven fuel pump & Horsepower up to 350 HP. For gravity fed systems, please see the FT90 part #10-01224.

The EI Fuel Flow Transducer FT 60 has two female 1/4" NPT (national pipe thread) ports. Adapters are also available to fit 1/4" NPT threads.

Part number 10-01165 and Part number 10-01196 are exactly the same part. Dynon uses the EI FT 60 for their systems.

Per EI, this would work.

Yes the transducer will always need to go downstream and before the servo is fine.

Yes, the EI FT60 uses 1/4" NPT fittings and wires needed to connect to your electrical system.

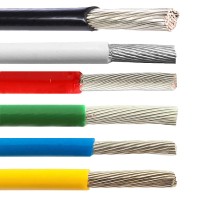

There is no wiring diagram available at this time. The red wire is +5V power, black is ground and the white wire is signal.

The FT-60 receives its power from the instrument it is connected to. Both 12 and 24V systems are compatible with this transducer.

There are short wires included which you will need to splice to connect with the gauge.

Aircraft Spruce Canada

Aircraft Spruce Canada