1-877-795-2278 | info@aircraftspruce.ca

Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

FREE SHIPPING ON ORDERS OVER $699 (SOME EXCLUSIONS APPLY) | 877-795-2278

Super Hc Powerband Prop Drive V-Belts

Select Size:

25 Inch26.5 Inch29 Inch30 InchSelect Band:

Single BandPowerbandOverview

|

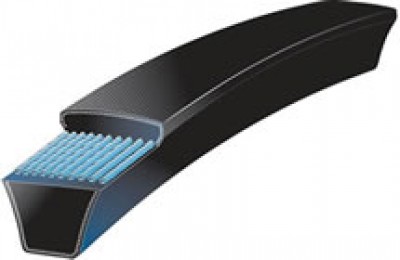

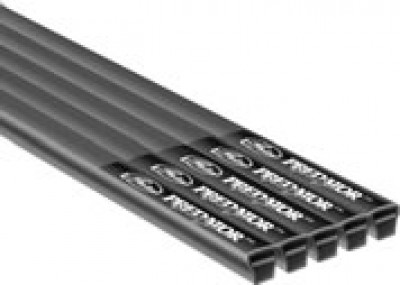

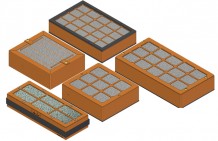

Reduction Drive Belts are available in: single band (Super HC®) or quad band (Super HC®PowerBand®) PowerBand® belts were developed by Gates for drives subjected to pulsating loads, shock loads or extreme vibrations where single belts could flip over on the pulleys. A high-strength tie band permanently joins two or more belts to provide lateral rigidity. This keeps the belts running in a straight line in the pulley grooves. PowerBand constructions is offered with Gates Predator® Hi-Power® II, Super HC® and Super HC Molded Notch Belts Super HC® Molded Notch V-Belts / Cross Sections: 3VX Super HC® Molded Notch belts are made with Gates exclusive EPDM construction for higher heat resistance and smoother running. They have specially designed notches and lateral rigidity to support the cord with precision-machined sidewalls for better length control, product uniformity and consistency. Gates molded notched V-belts, also referred to as cog belts, can save you up to 3% in energy savings compared to wrapped belts due to increased flexibility and reduced bending stress. Both Super HC® and Super HC® molded notch V-belts are part of the Gates V80 matching system. Both lines resist the effects of oil, heat, ozone, sunlight, weather and aging. They meet RMA standards for static conductivity and are available in both single strand and PowerBand® “joined” belt configurations. |

Aircraft Spruce Canada

Aircraft Spruce Canada